June 2017

ROV replaces divers in monopile installation workTechnological innovation strengthens Bluestream’s leading position in the offshore wind industry

ROV replaces divers in monopile installation work

Technological innovation strengthens Bluestream’s leading position in the offshore wind industry

In April this year, Den Helder-based offshore service provider Bluestream finished the offshore works for the Nordsee One successfully. For the first time in the history of the offshore wind industry, condition monitoring and ICCP systems were installed on the inside of five foundation piles of the Nordsee One offshore windfarm, in a remarkable, innovative approach. The initial intention of the client was to have the work undertaken by divers in the enclosed space inside the monopile. However, according to Bluestream, this operation could be very hazardous for the divers. In response, Bluestream developed a technical solution according to which a specially designed installation tool was operated by an ROV, so that the condition monitoring and ICCP systems could be safely attached to the inside of the monopile.

The 332 MW Nordsee One offshore wind project is situated approximately 40km north of the Island of Juist, in German territorial waters. With a total area of approximately 41km², the project’s 54 turbines will be located in one of the most favourable locations (high wind speed, <30m water depth, travel times within one-day window) in the North Sea. The project is owned by Northland Power Inc. (85%), and Innogy SE (15%).

Bluestream was aware that similar projects had led to fatal accidents in the past. For Bluestream this was sufficient reason to investigate the possibility of developing an innovative solution to eradicate the need for deploying divers inside the piles. Experts at Bluestream succeeded in developing and elaborating a brand-new concept into a fully fledged alternative, with a leading role for one of the company’s Remote Operated Vehicles (ROVs). The suggestion was made to the client Nordsee One to not have the tasks undertaken by divers but by an ROV with a specially designed remotely operated underwater installation tool. The challenge lay in the fact that in the design phase of the monopile, account had been taken of the fitting of the monitoring system by divers. As a result, the provisions installed during construction in fact required the bolting on of the sensor. In principle, this made these provisions unsuitable for installation by an ROV. In response, Bluestream developed a special installation tool that enabled one of its compact ROV systems to fit the sensors, as well as elaborating a modification to the original attachment mechanism with bolts that was initially considered exclusively suitable for manual installation by divers.

“Thanks to the innovative combination of existing techniques, Bluestream succeeded in a very short period of time in creating a solution for the remote installation of bolts in a monopile with limited working space,” explained Adriaen Winckers, responsible for Business Development at Bluestream. “Innovation and safety are the lifeblood of our company. We are a niche player that is constantly pushing the envelope. Bluestream concentrates on those segments of the market that cannot be served by just anyone. We strive continuously to deliver solutions within our range of services that no one else can offer and are dedicated in the extreme in the work we do for our clients. We as management are responsible for safely deploying our people on these projects. We believe in innovative technology and so we always deploy people with talent and creativity to consider every possible assignment in a clear and logical manner, so that they can come up with innovative solutions to make the work more effective and above all safer. Ideas often emerge from practice when the traditional solution is either insufficient, overly expensive or too risky.”

Based on the investment made by Bluestream in developing this new solution, the price quoted by the company was higher than for a conventional diver-based solution. Winckers continued: “It is evidence of a clear sense of reality that the management of Nordsee One nonetheless opted for our smart ROV solution according to which the entire operation could be carried out efficiently, effectively and above all safely. It goes without saying that we are grateful for the confidence they demonstrated in our innovative solution and in our multidisciplinary project organisation."

At the end of February this year, Bluestream received the official order to install accelerometers and Impressed Current Cathodic Protection (ICCP) reference cells on the inside of five foundation monopiles, using an ROV. Divers were also instructed to install two sonar transponders on the outside of the monopiles, to inspect water exchange openings and to fit two AWAC (Acoustic Waves and Current) sensors on the seabed. A start was made on actual implementation of the work at the end of March from on-board the offshore support vessel Island Crown built in 2013, and equipped with a walk-to-work system.

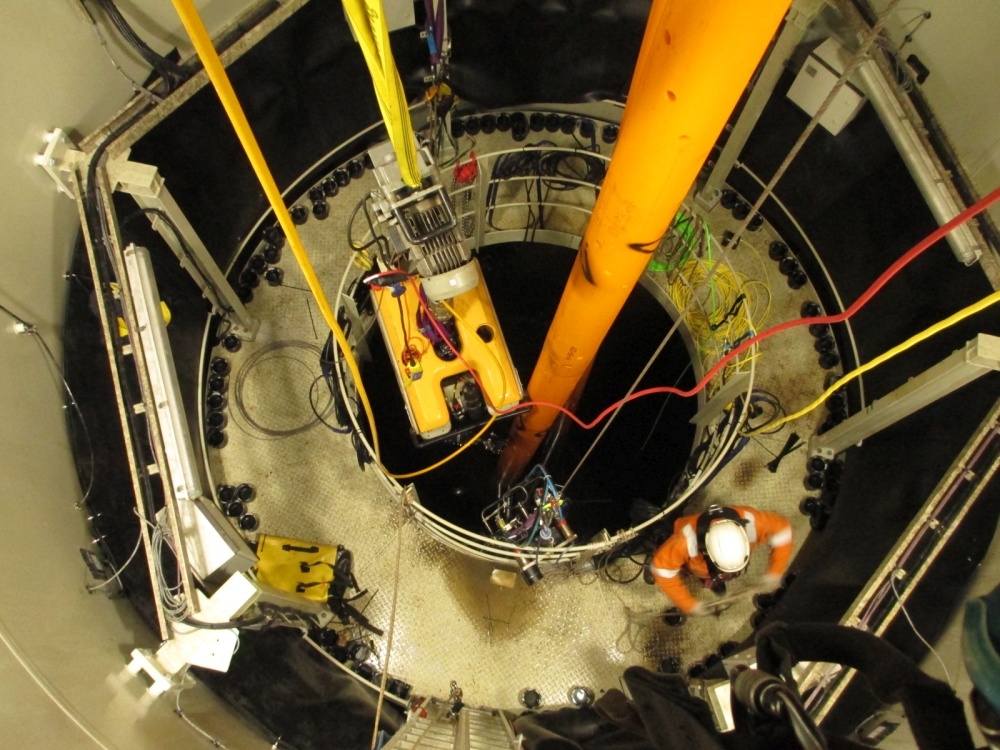

Seb Bevers, Project Manager at Bluestream explained: “Although the sum of the parts of this innovation was new, each individual part was in fact proven technology. In technical terms, therefore, this innovation, which has undergone extensive testing at our own test facility in Den Helder, was fully under control. The project was also a demonstration of the cooperation between the various disciplines within Bluestream: diving, ROV operations and rope access. To start with, the ROV had to be inserted in the monopile via a very narrow opening by our rope access technicians before our highly experienced ROV operators could set to work. Their greatest challenge was manoeuvring the ROV in the confined working space with a maximum diameter of just 6.5 metres, as well as holding the panel fitted with the condition monitoring and ICCP systems still while the M24 bolts were tightened. Due to the limited visibility we deployed a second small ROV to give us an extra set of eyes in the water. Prior to the offshore implementation of the entire installation process, members of our rope access team first carried out a site inspection to make sure we had a perfect picture of the situation in the monopile.”

After three weeks of working night and day, the Nordsee One offshore windfarm project was successfully completed by Bluestream towards the end of April. During the project highpoint, Bluestream had a project team of no less than 23 people on site, all of them enthusiastic professionals who worked with total dedication, without losing sight of the safety aspects for a single moment.

Daniel Waugh, Offshore Works Package Manager at Nordsee One looked back on the collaboration with Bluestream with clear satisfaction. “All systems were installed in a timely manner, as per our installation requirements, with no issues to report and without a single incident. The innovative solution they developed and the technical solutions they proposed all proved highly successful.”